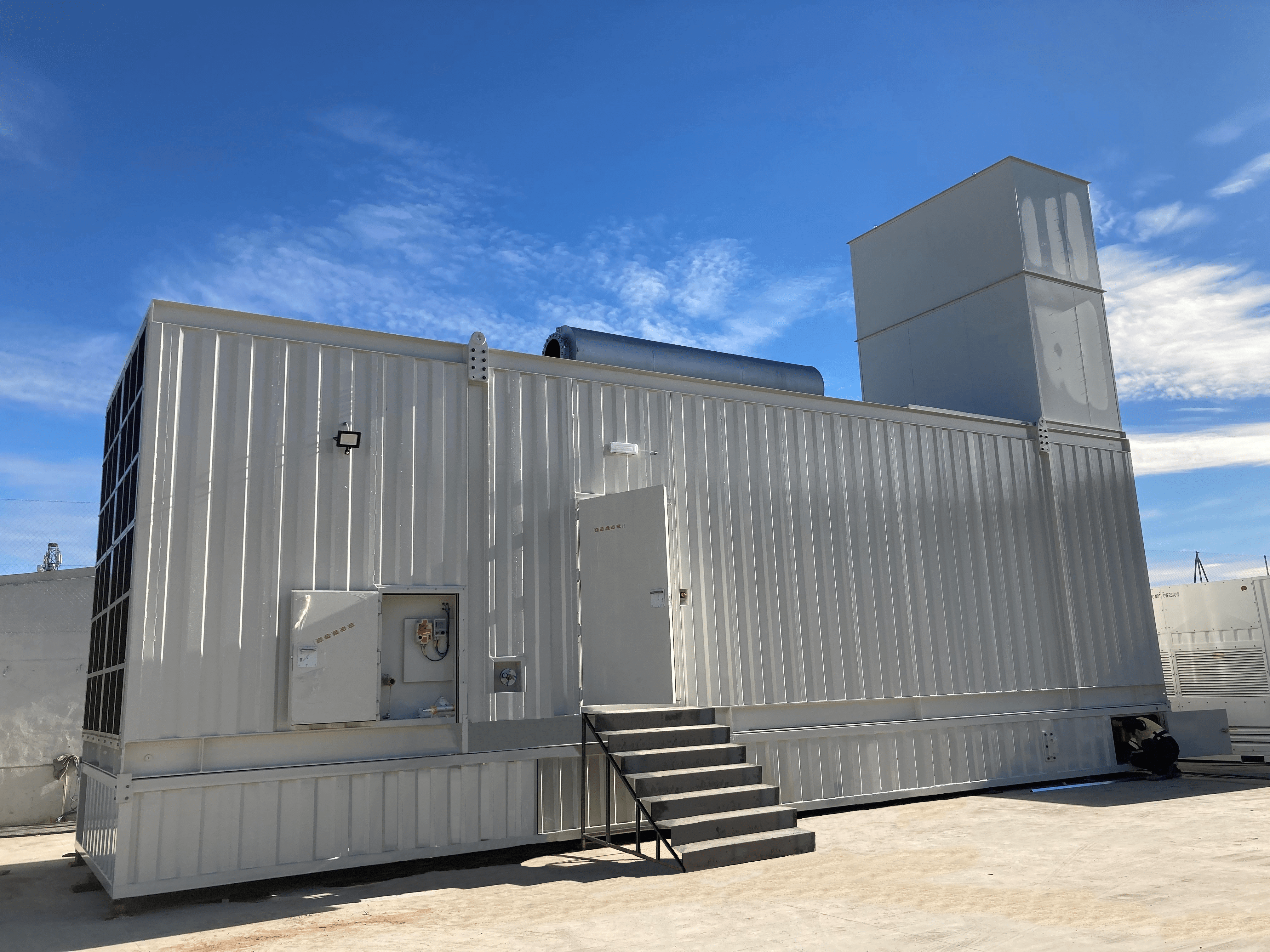

Our containers are manufactured in accordance with international standards for sea, air or land transport and we are able to adapting to any needand requirement. We manufacture laterally expandable containers, modular compartmentalised containers and any other customised solution.

STANDARDISED

MODULAR

CUSTOMISED

EXPANDABLE